Motorcycle Parts New Zealand Specialists - Questions

Table of ContentsSome Ideas on Motorcycle Parts New Zealand Specialists You Need To KnowIndicators on Motorcycle Parts New Zealand Specialists You Need To Know6 Easy Facts About Motorcycle Parts New Zealand Specialists ExplainedFascination About Motorcycle Parts New Zealand SpecialistsFacts About Motorcycle Parts New Zealand Specialists UncoveredNot known Details About Motorcycle Parts New Zealand Specialists The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is DiscussingThe Of Motorcycle Parts New Zealand Specialists

So, connect to one of our professionals today.CNC machining technology is swiftly coming to be the centerpiece of various manufacturing processes around the world as a direct outcome of its numerous advantages over various other approaches. Furthermore, the sectors that produce motorcycles have hopped on board with this pattern. The most cutting-edge business are now creating their engine components and wheels making use of machining strategies initially developed for motorcycle parts.

On the various other hand, the effects of market are the key emphasis of this article. Let's get directly into it. You may be questioning why we utilize. It is not hard to fathom the factors that caused this result. Currently that we have your attention allow us explain the rationale behind this modern growth in the bike manufacturing sector.

The Ultimate Guide To Motorcycle Parts New Zealand Specialists

In enhancement, you have total control over the look of the parts, even down to the min information. Occasionally, motorcyclists may choose to fix up their trip by installing aftermarket elements or modifying the bike's makeover. As soon as once more, computer system numerical control (CNC) machining is the most useful technique. Upgrades may be of any kind of type and style you want.

The 6-Minute Rule for Motorcycle Parts New Zealand Specialists

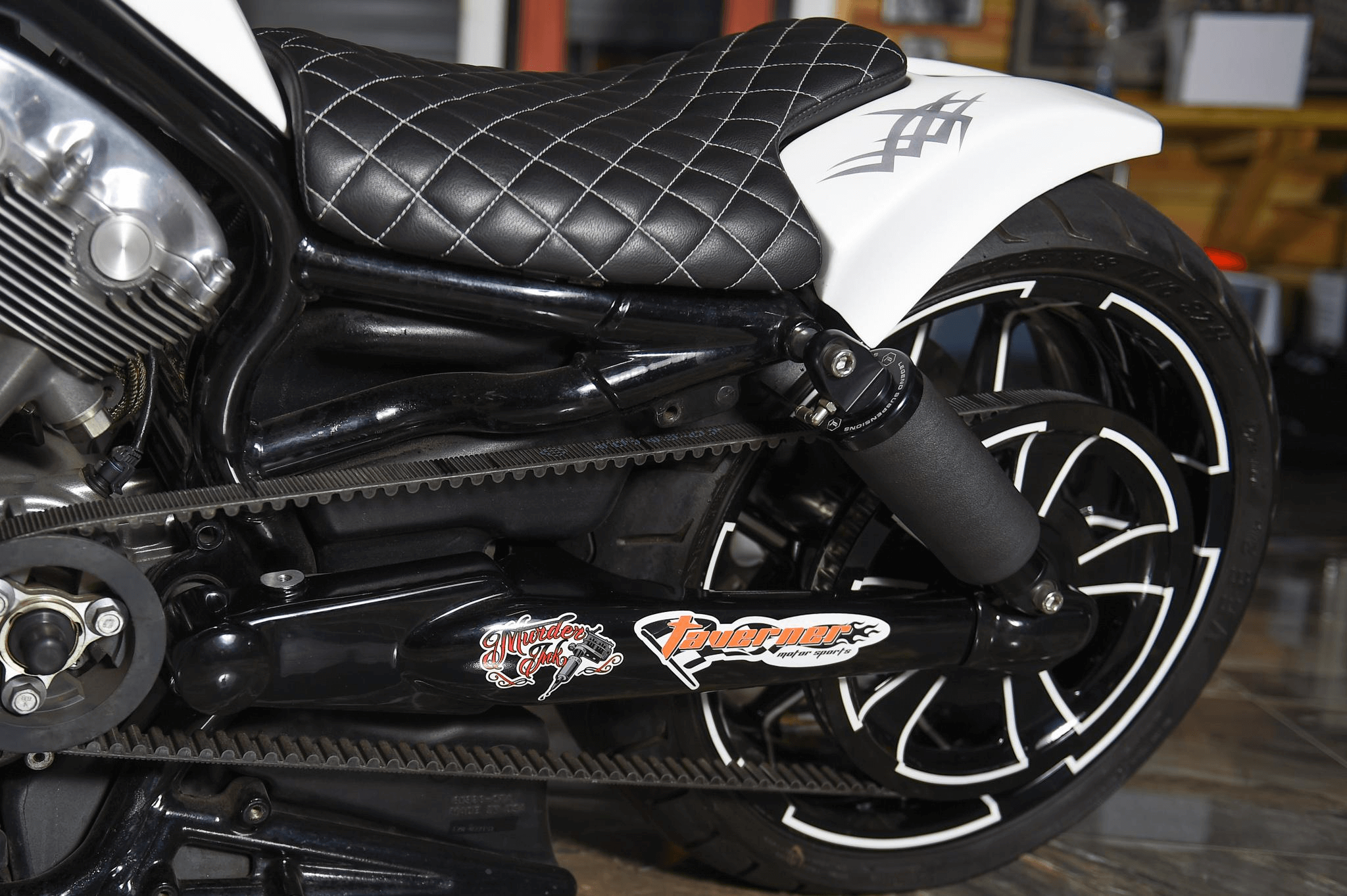

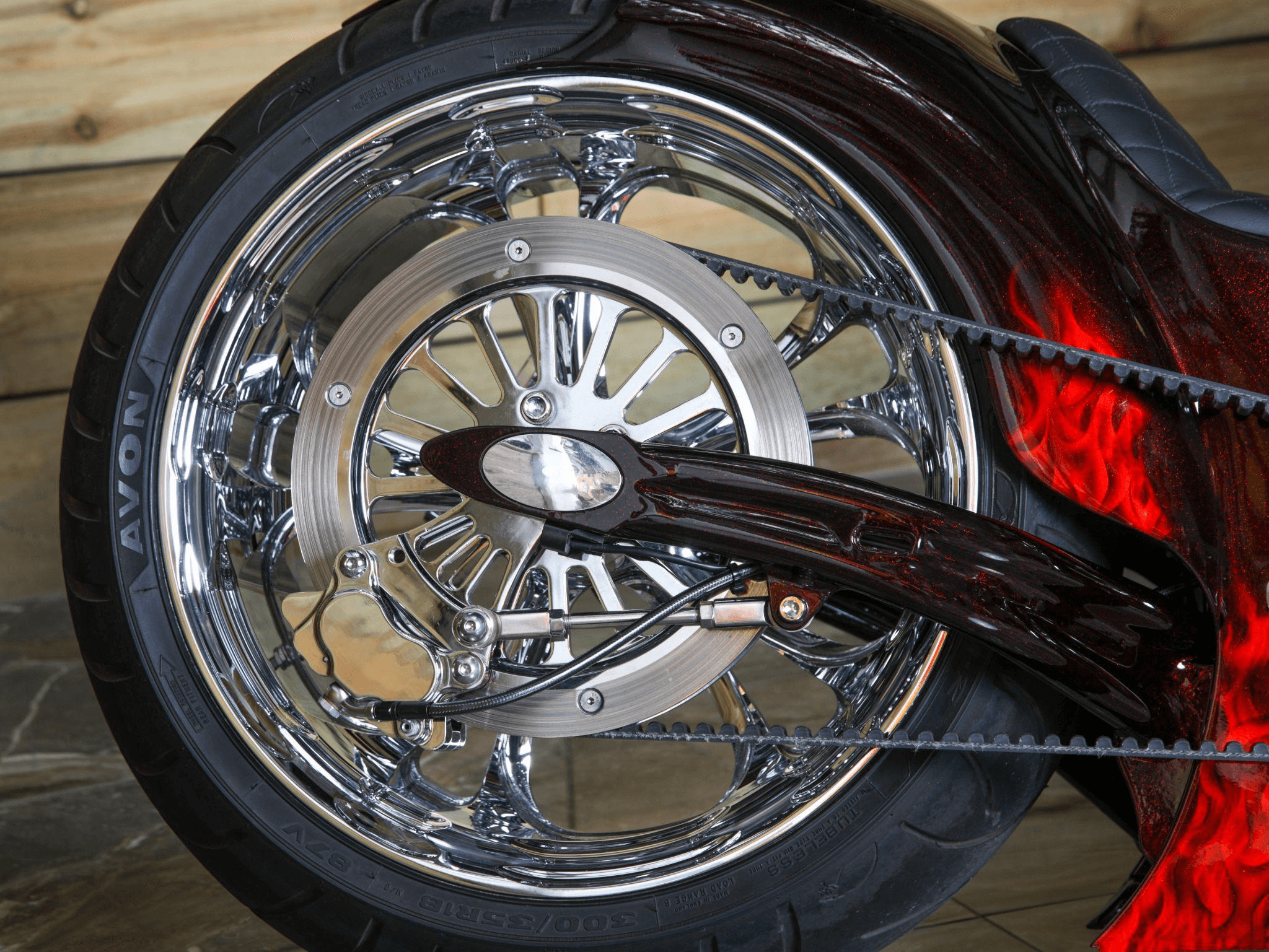

CNC machining might be made use of to make nearly all of a bike's metal and plastic components. To continue, we'll talk about a number of machined parts for motorcycles. In contrast to those on vehicles, wheels on bikes have a tendency to be more noticeable. Because of this, the bike's looks may be improved with the proper personalization of these wheels.

Milling treatments are utilized to get the desired level of wheel customization. An additional facet of the motorcycle that might be personalized is the tires.

An Unbiased View of Motorcycle Parts New Zealand Specialists

When it concerns a car (or a motorbike), one of the most important part is the engine. Numerous people mention it as the "heart" of the automobile. On the various other hand, the camshaft, the cyndrical tube head, and the pistons tend to be detailed and call for layouts with a high degree of accuracy.

Usage just top quality products, however, considering that these lights are essential for the safety of motorcyclists and various other vehicle drivers or people on the roadway, specifically at evening. Motorbike fronts lights have 3 main parts: the light bulb, or light resource, the lens, and the housing.

Milling processes with a remarkable surface would certainly cause the lenses having a reflective top quality that resembles that of a mirror. The check out here cover, on the various other hand, is not composed of fragile products; instead, it is built out of difficult polymers that can be machined into more elaborate patterns.

Excitement About Motorcycle Parts New Zealand Specialists

Bike producers often cast these parts, but just for the production of bespoke components. Machining on five axes in today's globe is the methods by which any type of layout form may be realized.

The success of the procedure is contingent on the mill cutters' capability to determine refined and complicated angles precisely. Choose Runsom for your tailored motorbike parts! We have the capability to make complex see this page and elegant components making your motorbike matchless. A lot of are crafted from aluminum or steel alloys, each of which has its uses and advantages.

Here are a few instances of steels usually made use of in motorcycle element machining. Aluminum is the main product utilized by firms concentrating on generating customized motorbike parts to create a lot of these parts. In the past, we would certainly construct our engines out of actors iron. On the various other hand, light weight aluminum is rapidly ending up being the product of selection, partially as a result of the truth that it is a lot more lightweight.

Zinc refers to an additional steel that is very light in weight and has wonderful machining qualities because of its high mechanical stamina. This material might be formed into almost any shape and maintains its measurements well. Also mission-critical parts that need a high degree of precision may profit from their use.

An Unbiased View of Motorcycle Parts New Zealand Specialists

Another metal that sees heavy usage in the production use this link of CNC-customized components is magnesium. It is among the lightest metals that are now obtainable and has exceptional machinability attributes and toughness appropriate with its reduced weight. Among the downsides of magnesium is that its dust might conveniently capture fire.

As a result of its superior machinability and weldability, stainless-steel is an alloy that is specifically fit for CNC processes. In addition to this, they have great corrosion resistance and a high aesthetic appeal. Their most common use in generating different bike components is bolts, such as screws and bolts. Their reduced susceptibility to oxidation and deterioration makes them perfect for this use.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Discussing

It appears that CNC transforming and crushing are the foundational procedures. In enhancement, it needs maintaining bars of material, most often plastic or steel, in setting and after that twisting a reducing tool to remove areas of the material as the material is transformed.

These approaches are similarly essential and produce elements with high precision and regular quality. The procedures assist boost the general quality of the machined motorbike parts.

10 Easy Facts About Motorcycle Parts New Zealand Specialists Shown